Carbide Ball Nose Short Flute End Mills - 2 Flute

碳化鎢快削型球銑刀- 二刃

碳化鎢快削型球銑刀- 二刃

Carbide Super Ball Nose Short Flute End Mills - 2 Flute

高速切削條件表

高速切削條件表

High-Speed Milling Conditions

| 被削材 Work Material |

合金鋼. 工具鋼 (30~45HRC) Alloy steel, Tool steel 預硬鋼, SKD61, NAK 等Prehardned steel, AISI H13 |

熱處理鋼 (45~55HRC) Hardned steel SKD61, SKD11, NAK, STAVAX 等 |

熱處理鋼 (55~65HRC) Hardned steel SKD11 AISI D2 等 |

|||||

| 切削速度 Cutting Speed |

高速條件 | 高速條件 | 高速條件 | |||||

| R: 球頭半徑 Radius |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

||

| 0.5 | 40000 | 2500 | 30000 | 2000 | 25000 | 1400 | ||

| 0.75 | 30000 | 3000 | 30000 | 2500 | 25000 | 2000 | ||

| 1 | 25000 | 3000 | 25000 | 2500 | 20000 | 2000 | ||

| 1.5 | 20000 | 3000 | 18000 | 2500 | 14000 | 2000 | ||

| 2 | 20000 | 3000 | 16000 | 2500 | 14000 | 2000 | ||

| 2.5 | 18000 | 3000 | 12000 | 2500 | 12000 | 2000 | ||

| 3 | 16000 | 3000 | 8000 | 2500 | 7000 | 2000 | ||

| 4 | 10000 | 2500 | 7000 | 1800 | 5000 | 1200 | ||

| 5 | 7000 | 2000 | 5000 | 1500 | 4000 | 1000 | ||

| 6 | 5000 | 1500 | 4000 | 1200 | 3000 | 800 | ||

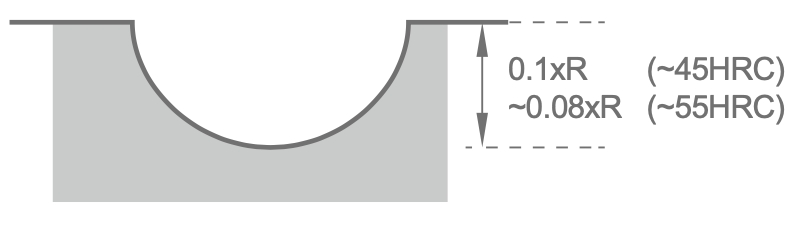

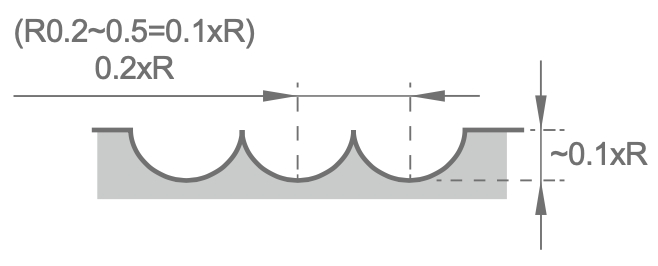

切削量基準 Depth of cut D( 直徑 Dia.) |

|

|

||||||

注意事項:

1. 溝加工時之進給速度,請設定為上述值之60%。

2. 請使用油霧(Oil-mist)冷卻或吹氣方式(Air-blow)進行切削。

3. 機械設備或工件的夾持剛性不足,出現震動時,請以相同比例按上表降低回轉數及進給速度。

4. 請使用較具有剛性之機械設備及夾頭。

Notes:

1.When slotting, reduce the feed by 60% from above values.

2.Use Oil-mist or Air-blow coolant.

3.If the rigidity of the machine or the work material intallation is very low, or chattering is generated, please reduce the revolution and the feed rate

proportionately.

4.Use a rigid machine and holder.

1. 溝加工時之進給速度,請設定為上述值之60%。

2. 請使用油霧(Oil-mist)冷卻或吹氣方式(Air-blow)進行切削。

3. 機械設備或工件的夾持剛性不足,出現震動時,請以相同比例按上表降低回轉數及進給速度。

4. 請使用較具有剛性之機械設備及夾頭。

Notes:

1.When slotting, reduce the feed by 60% from above values.

2.Use Oil-mist or Air-blow coolant.

3.If the rigidity of the machine or the work material intallation is very low, or chattering is generated, please reduce the revolution and the feed rate

proportionately.

4.Use a rigid machine and holder.