Carbide Ball Nose Standard End Mills - 2 Flute

| 被削材 Work Material |

炭素鋼. 合金鋼 (~30HRC) Carbon steel, Alloy steel S50C, SCM, 鑄鐵FC250 等 AISI 1049, Cast iron |

合金鋼. 工具鋼 (30~45HRC) Alloy steel, Tool steel 預硬鋼, SKD61, NAK 等Prehardned steel, AISI H13 |

沃斯田鐵系列不鏽鋼 Austenitic stainless steel SUS304, SUS316 等AISI 304, AISI316 |

熱處理鋼 (45~55HRC) Hardned steel SKD61, SKD11, NAK, STAVA X 等AISI H13 |

熱處理鋼 (55~60HRC) Hardned steel SKD11 等AISI D2 |

||||||||

| 切削速度 Cutting Speed |

150 m/min | 120~150 m/min | 80~100 m/min | 高速條件 | 高速條件 | ||||||||

| R: 球頭半徑 Radius |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

|||

| 0.1 | 50000 | 400 | 50000 | 340 | 50000 | 200 | 20000 | 250 | 20000 | 250 | |||

| 0.2 | 50000 | 620 | 50000 | 600 | 50000 | 620 | 20000 | 320 | 20000 | 320 | |||

| 0.3 | 50000 | 920 | 50000 | 940 | 50000 | 900 | 20000 | 460 | 20000 | 460 | |||

| 0.4 | 50000 | 1200 | 48000 | 1200 | 48000 | 900 | 20000 | 580 | 20000 | 580 | |||

| 0.5 | 48000 | 1400 | 38000 | 1200 | 28000 | 900 | 20000 | 1200 | 20000 | 800 | |||

| 0.75 | 30000 | 1200 | 24000 | 1000 | 18000 | 680 | 20000 | 1600 | 20000 | 1200 | |||

| 1 | 24000 | 1100 | 18000 | 800 | 14000 | 600 | 20000 | 2400 | 20000 | 2000 | |||

| 1.5 | 16000 | 920 | 13000 | 600 | 9600 | 460 | 16000 | 2400 | 14000 | 2000 | |||

| 2 | 12000 | 920 | 10000 | 580 | 7200 | 460 | 12000 | 2000 | 9600 | 1600 | |||

| 2.5 | 9600 | 920 | 8000 | 560 | 5800 | 460 | 9600 | 2000 | 7600 | 1200 | |||

| 3 | 8000 | 920 | 6400 | 540 | 4800 | 460 | 8000 | 1600 | 6400 | 1000 | |||

| 4 | 6000 | 900 | 4800 | 540 | 3600 | 460 | 4000 | 1000 | 4000 | 800 | |||

| 5 | 4800 | 900 | 3800 | 540 | 2800 | 460 | 3200 | 1000 | 3200 | 800 | |||

| 6 | 4000 | 900 | 3200 | 540 | 2400 | 460 | 2800 | 1000 | 2800 | 800 | |||

| 8 | 3000 | 900 | 2400 | 540 | 2000 | 460 | 2400 | 800 | ― | ― | |||

| 10 | 2400 | 900 | 1800 | 520 | 1400 | 460 | 1800 | 800 | ― | ― | |||

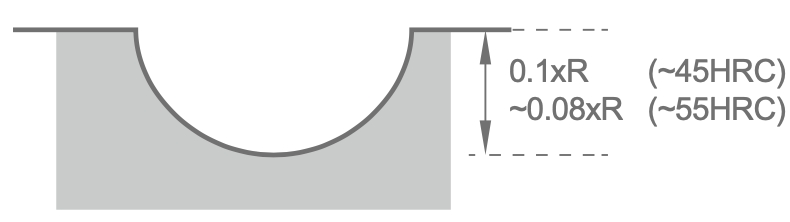

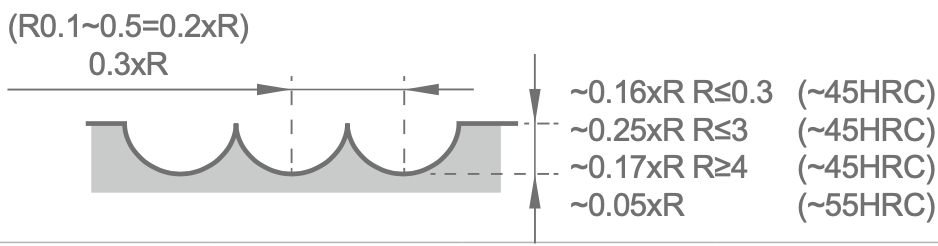

切削量基準 Depth of cut D( 直徑 Dia.) |

|

|

|||||||||||

碳化鎢球銑刀- 四刃

Carbide Ball Nose Standard End Mills - 4 Flute

| 被削材 Work Material |

炭素鋼. 合金鋼 (~30HRC) Carbon steel, Alloy steel S50C, SCM, 鑄鐵FC250 等 AISI 1049, Cast iron |

合金鋼. 工具鋼 (30~45HRC) Alloy steel, Tool steel 預硬鋼, SKD61, NAK 等Prehardned steel, AISI H13 |

沃斯田鐵系列不鏽鋼 Austenitic stainless steel SUS304, SUS316 等AISI 304, AISI316 |

熱處理鋼 (45~55HRC) Hardned steel SKD61, SKD11, NAK, STAVAX 等AISI H13 |

熱處理鋼 (55~60HRC) Hardned steel SKD11 等AISI D2 |

|||||||||

| 切削速度 Cutting Speed |

150 m/min | 120~150 m/min | 80~100 m/min | 高速條件 | 高速條件 | |||||||||

| R: 球頭半徑 Radius |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

||||

| 1.5 | 16000 | 1400 | 13000 | 900 | 9600 | 680 | 16000 | 3000 | 14000 | 2600 | ||||

| 2 | 12000 | 1400 | 10000 | 860 | 7200 | 680 | 12000 | 2600 | 9600 | 2600 | ||||

| 2.5 | 9600 | 1400 | 8000 | 840 | 5800 | 680 | 9600 | 2600 | 7600 | 1600 | ||||

| 3 | 8000 | 1400 | 6400 | 800 | 4800 | 680 | 8000 | 2000 | 6400 | 1300 | ||||

| 4 | 6000 | 1320 | 4800 | 800 | 3600 | 680 | 4000 | 1400 | 4000 | 1000 | ||||

| 5 | 4800 | 1320 | 3800 | 800 | 2800 | 680 | 3200 | 1400 | 3200 | 1000 | ||||

| 6 | 4000 | 1320 | 3200 | 800 | 2400 | 680 | 2800 | 1400 | 2800 | 1000 | ||||

| 8 | 3000 | 1320 | 2800 | 800 | 2000 | 680 | 2400 | 1000 | ― | ― | ||||

| 10 | 2400 | 1320 | 1800 | 780 | 1400 | 680 | 1800 | 1000 | ― | ― | ||||

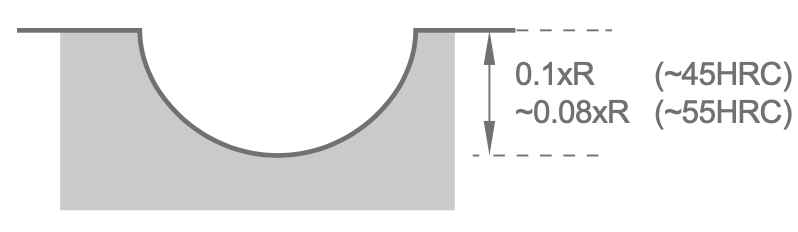

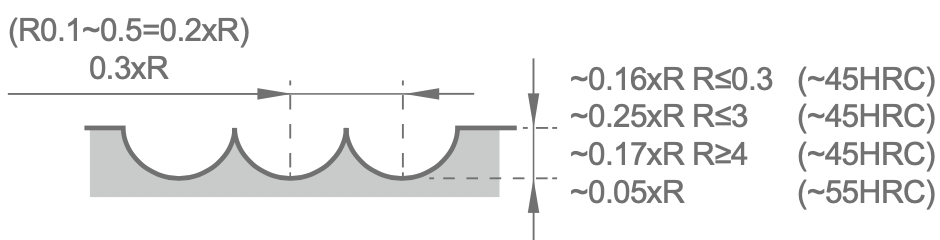

切削量基準 Depth of cut D( 直徑 Dia.) |

|

|

||||||||||||

1. 溝加工時之進給速度,請設定為上述值之60%。

2. 刀具夾持突出量,以4D 為基準,超出上述場合時,請將切削條件作適度之調整。

3. 請使用油霧(Oil-mist)冷卻或吹氣方式(Air-blow)進行切割。

4. 主軸回轉及床台進給速度,請以相同比例作適度調整。

Notes:

1.When slotting, reduce the feed by 60% from above values.

2.Length of overhang is 4 times dia. As standard. When it is longer then 4 times dia. Follow figures of above table.

3.Use Oil-mist or Air-blow coolant.

4.Adjust both spindle speed and feed according to milling conditions and machine rigidity.