Carbide Square Type Standard End Mill For Hard Stell - 6 Flute

| 被削材 Work Material |

熱處理鋼 ~50HRC Hardned steel SKD61,HPM 等 |

熱處理鋼 (50~55HRC) Hardned steel SKD61, SKD11, NAK, STAVAX 等 |

熱處理鋼 (55~60HRC) Hardned steel SKD11 AISI D2 等 |

||||||||||||

| 切削速度 Cutting Speed |

30~80 m/min | 30~70 m/min | 20~60 m/min | ||||||||||||

| 直徑 (mm) Diameter |

進給速度 mm/min Feed Rate |

進給速度 mm/min Feed Rate |

進給速度 mm/min Feed Rate |

||||||||||||

| 回轉數 (min-1) Speed |

側面 Side Milling |

回轉數 (min-1) Speed |

溝 Slotting |

回轉數 (min-1) Speed |

側面 Side Milling |

回轉數 (min-1) Speed |

溝 Slotting |

回轉數 (min-1) Speed |

側面 Side Milling |

回轉數 (min-1) Speed |

溝 Slotting |

||||

| 3 | 3800 | 520 | 2000 | 260 | 3200 | 380 | 1600 | 800 | 2600 | 260 | 1300 | 130 | |||

| 4 | 2800 | 450 | 1400 | 230 | 2400 | 360 | 1200 | 180 | 2000 | 260 | 1000 | 130 | |||

| 5 | 5000 | 1200 | 2600 | 600 | 4500 | 1000 | 2300 | 500 | 3800 | 800 | 1900 | 400 | |||

| 6 | 4200 | 1300 | 2500 | 780 | 3700 | 1100 | 2200 | 660 | 3200 | 680 | 1600 | 340 | |||

| 8 | 3200 | 1500 | 1900 | 900 | 2800 | 1300 | 1700 | 780 | 2400 | 750 | 1200 | 380 | |||

| 10 | 2600 | 1500 | 1600 | 900 | 2200 | 1300 | 1300 | 780 | 1900 | 900 | 900 | 450 | |||

| 12 | 2100 | 1300 | 1300 | 780 | 1900 | 1100 | 1100 | 660 | 1600 | 960 | 800 | 480 | |||

| 16 | 1600 | 1200 | 1000 | 650 | 1400 | 900 | 900 | 500 | 1200 | 760 | 680 | 400 | |||

| 20 | 1200 | 1000 | 1000 | 500 | 1100 | 800 | 800 | 450 | 1000 | 700 | 600 | 400 | |||

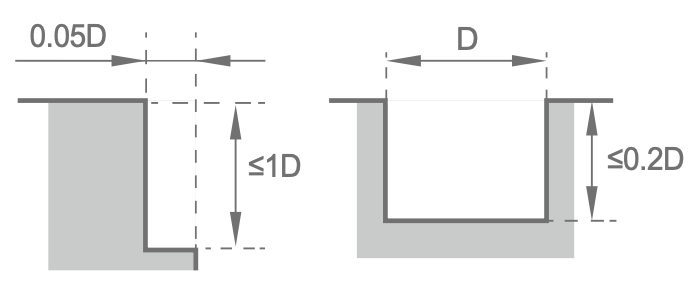

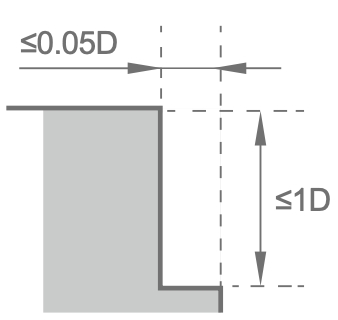

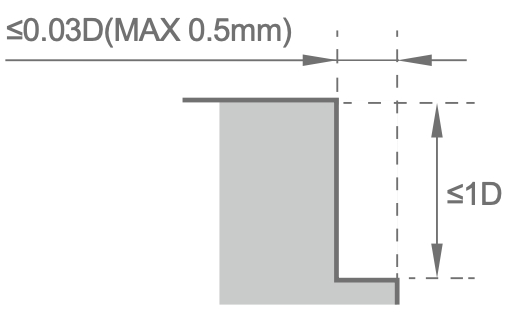

切削量基準 Depth of cut D( 直徑 Dia.) |

|

|

|

||||||||||||

注意事項:

1. 機械設備或工件的夾持剛性不足,出現震動時,請以相同比例按上表降低回轉數及進給速度。

2. 側面加工時,請以下銑法(順銑法)進行。

3. 請使用油霧(Oil-mist)冷卻或吹氣方式(Air-blow)進行切割。

Notes:

1.If the rigidity of the machine of the work material installation is very low, or chattering is generated, please reduce the revolution and the feed rate

proportionately.

2.Climb cut is recommended for side milling.

3.Use Oil-mist or Air-blow coolant.

碳化鎢端銑刀 - 六刃- 高速切削條件表

1. 機械設備或工件的夾持剛性不足,出現震動時,請以相同比例按上表降低回轉數及進給速度。

2. 側面加工時,請以下銑法(順銑法)進行。

3. 請使用油霧(Oil-mist)冷卻或吹氣方式(Air-blow)進行切割。

Notes:

1.If the rigidity of the machine of the work material installation is very low, or chattering is generated, please reduce the revolution and the feed rate

proportionately.

2.Climb cut is recommended for side milling.

3.Use Oil-mist or Air-blow coolant.

碳化鎢端銑刀 - 六刃- 高速切削條件表

Carbide Square Type Standard End Mill For Hard Stell - 6 Flute, High-Speed Milling Conditions

| 被削材 Work Material |

熱處理鋼 ~50HRC Hardned steel SKD61,HPM 等 |

熱處理鋼 (50~55HRC) Hardned steel SKD61, SKD11, NAK, STAVAX 等 |

熱處理鋼 (55~60HRC) Hardned steel SKD11 AISI D2 等 |

||||||||||||

| 切削速度 Cutting Speed |

80~140 m/min | 75~120 m/min | 45~100 m/min | ||||||||||||

| 直徑 (mm) Diameter |

進給速度 mm/min Feed Rate |

進給速度 mm/min Feed Rate |

進給速度 mm/min Feed Rate |

||||||||||||

| 回轉數 (min-1) Speed |

側面 Side Milling |

回轉數 (min-1) Speed |

溝 Slotting |

回轉數 (min-1) Speed |

側面 Side Milling |

回轉數 (min-1) Speed |

溝 Slotting |

回轉數 (min-1) Speed |

側面 Side Milling |

回轉數 (min-1) Speed |

溝 Slotting |

||||

| 3 | 11000 | 1500 | 5400 | 750 | 9600 | 1100 | 4800 | 550 | 7400 | 740 | 3700 | 370 | |||

| 4 | 8000 | 1300 | 4000 | 650 | 7200 | 1100 | 3600 | 550 | 5600 | 740 | 2800 | 370 | |||

| 5 | 9000 | 2100 | 4600 | 1100 | 7600 | 1800 | 3800 | 900 | 5200 | 1100 | 2600 | 550 | |||

| 6 | 7400 | 2200 | 4500 | 1300 | 6400 | 1900 | 3900 | 1150 | 5300 | 1100 | 2700 | 550 | |||

| 8 | 5600 | 2600 | 3400 | 1560 | 4800 | 2200 | 2900 | 1320 | 4000 | 1300 | 2000 | 650 | |||

| 10 | 4500 | 2600 | 2700 | 1560 | 3800 | 2200 | 2400 | 1320 | 3200 | 1500 | 1600 | 740 | |||

| 12 | 3700 | 2200 | 2200 | 1320 | 3200 | 1900 | 2000 | 1100 | 2600 | 1600 | 1300 | 800 | |||

| 16 | 2800 | 2200 | 1600 | 1320 | 2400 | 1900 | 1400 | 1100 | 2000 | 1600 | 1000 | 800 | |||

| 20 | 2200 | 1800 | 1300 | 960 | 1920 | 1500 | 1200 | 960 | 1600 | 1280 | 760 | 600 | |||

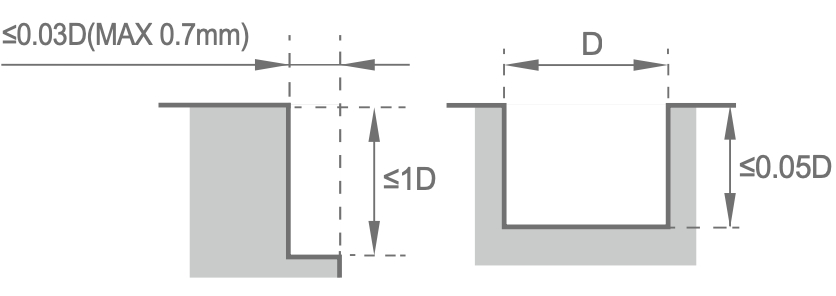

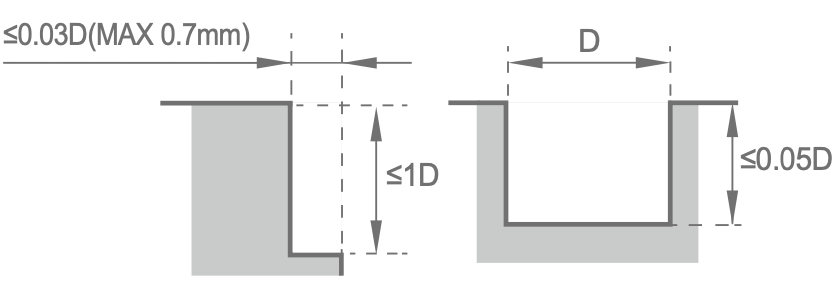

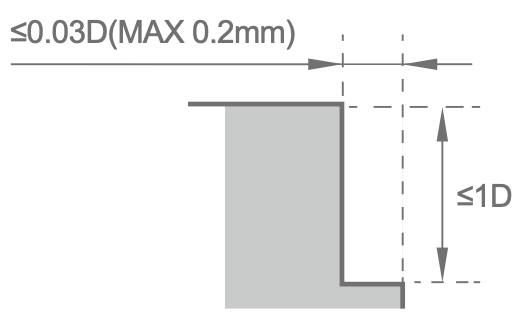

切削量基準 Depth of cut D( 直徑 Dia.) |

|

|

|

||||||||||||