Carbide Corner Radius Standard End Mills - 2 Flute

| 被削材 Work Material |

炭素鋼 . 合金鋼 (~30HRC) Carbon steel, Alloy steel S50C, SCM, 鑄鐵 FC250 等 AISI 1049, Cast iron |

合金鋼 . 工具鋼 (30~45HRC) Alloy steel, Tool steel 預硬鋼 , SKD61, NAK 等 Prehardned steel, AISI H13 |

沃斯田鐵系列不鏽鋼 Austenitic stainless steel SUS304, SUS316 等 AISI316 |

熱處理鋼 (~55HRC) Hardned steel SKD61, SKD11, NAK, STAVAX 等 AISI H13 |

||||||||

| 切削速度 Cutting Speed |

60~80 m/min | 50~70 m/min | 30~50 m/min | 20~30 m/min | ||||||||

| 直徑 (mm) Diameter |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Spee |

進給速度 mm/min Feed Rate |

||||

| 側面 Side Milling |

溝 Slotting |

側面 Side Milling |

溝 Slotting |

側面 Side Milling |

溝 Slotting |

側面 Side Milling |

溝 Slotting |

|||||

| 1 | 25000 | 200 | 100 | 19000 | 130 | 50 | 12800 | 80 | 40 | 6400 | 60 | 30 |

| 1.5 | 17000 | 340 | 120 | 12000 | 180 | 60 | 8500 | 90 | 45 | 4200 | 70 | 35 |

| 2 | 12000 | 400 | 150 | 9600 | 210 | 70 | 6400 | 110 | 55 | 3200 | 80 | 40 |

| 3 | 8500 | 450 | 160 | 6400 | 250 | 80 | 4300 | 120 | 60 | 2100 | 100 | 50 |

| 4 | 6400 | 450 | 160 | 4800 | 250 | 80 | 3200 | 120 | 60 | 1600 | 100 | 50 |

| 6 | 4200 | 500 | 200 | 3200 | 270 | 90 | 2100 | 150 | 70 | 1000 | 120 | 60 |

| 8 | 3200 | 540 | 220 | 2400 | 300 | 100 | 1600 | 170 | 80 | 800 | 140 | 70 |

| 10 | 2560 | 560 | 240 | 1900 | 320 | 110 | 1200 | 190 | 90 | 640 | 160 | 80 |

| 12 | 2100 | 580 | 260 | 1600 | 340 | 120 | 1000 | 200 | 100 | 540 | 180 | 90 |

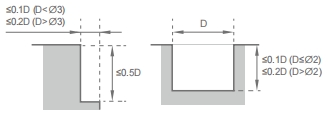

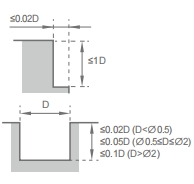

切削量基準 Depth of cut D( 直徑 Dia.) |

|

|

||||||||||

注意事項:

1. 切削沃斯田鐵系列不鏽鋼時,請使用非水溶性切削油效果較好。

2. 機械設備或工件的夾持剛性不足,出現震動時,請以相同比例按上表降低回轉數及進給速度。

3. 縱向進給時,進給速度請設定為上表之 1/3 以下。

Notes:

1.In cutting Austenitic stainless steels, the use of non-water-soluble cutting fluid is especially effective.

2.If the rigidity of the machine of the work material installation is very low, or chattering is generated, please reduce the revolution and the feed rate

proportionately.

3.When drilling, please set the feed rate at 1/3 or below of the above value

1. 切削沃斯田鐵系列不鏽鋼時,請使用非水溶性切削油效果較好。

2. 機械設備或工件的夾持剛性不足,出現震動時,請以相同比例按上表降低回轉數及進給速度。

3. 縱向進給時,進給速度請設定為上表之 1/3 以下。

Notes:

1.In cutting Austenitic stainless steels, the use of non-water-soluble cutting fluid is especially effective.

2.If the rigidity of the machine of the work material installation is very low, or chattering is generated, please reduce the revolution and the feed rate

proportionately.

3.When drilling, please set the feed rate at 1/3 or below of the above value