Carbide Super Corner Radius Short Flute End Mills - 4 Flute

等高高速切削條件表

等高高速切削條件表

High-Speed Milling Conditions

| 被削材 Work Material |

炭素鋼. 合金鋼 (~30HRC) Carbon steel, Alloy steel S50C, SCM, 鑄鐵FC250 等AISI 1049, Cast iron |

合金鋼. 工具鋼 (30~45HRC) Alloy steel, Tool steel 預硬鋼, SKD61, NAK 等Prehardned steel, AISI H13 |

熱處理鋼 (45~55HRC) Hardned steel SKD61, SKD11, NAK, STAVAX 等 AISI H13 |

熱處理鋼 (55~65HRC) Hardned steel SKD11 AISI D2 等 |

|||||||

| 切削速度 Cutting Speed |

高速條件 | 高速條件 | 高速條件 | 高速條件 | |||||||

| 直徑 (mm) Diameter |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

|||

| 3 | 20000 | 11000 | 15000 | 8000 | 15000 | 7400 | 10000 | 3200 | |||

| 4 | 16000 | 11000 | 12000 | 8600 | 12000 | 7600 | 7600 | 3300 | |||

| 5 | 12000 | 12000 | 9000 | 9000 | 9000 | 8000 | 6000 | 3600 | |||

| 6 | 10000 | 12000 | 7600 | 9000 | 7600 | 8000 | 5000 | 3600 | |||

| 8 | 7800 | 12000 | 5800 | 9000 | 5800 | 8000 | 3800 | 3600 | |||

| 10 | 6200 | 12000 | 4600 | 9000 | 4600 | 8000 | 3000 | 3600 | |||

| 12 | 5200 | 12000 | 3800 | 9000 | 3800 | 8000 | 2600 | 3600 | |||

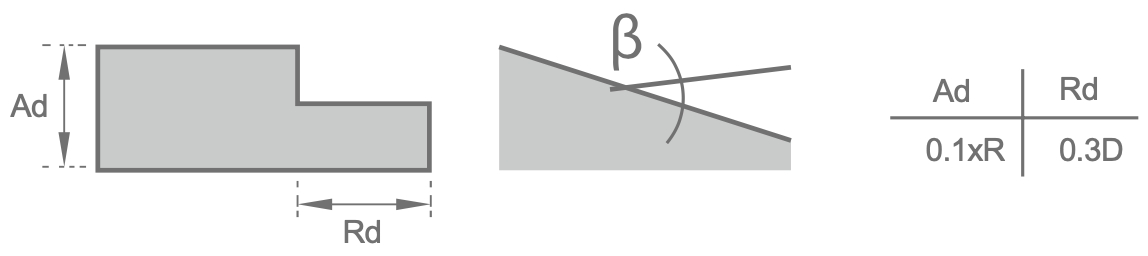

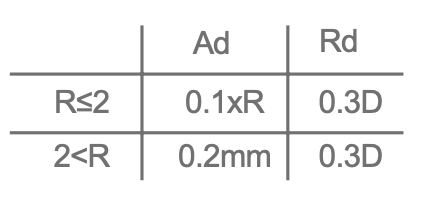

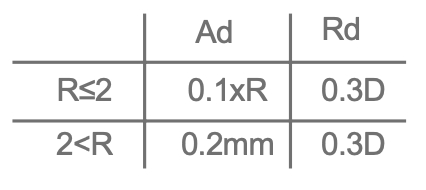

切削量基準 Depth of cut D( 直徑 Dia.) |

|

|

|

||||||||

注意事項:

1. 請使用剛性及精準備度較佳之機械與刀桿。

2. 這些切削條件是以在轉角處可作圓形插入銑削的前提下,如果是轉角為90 度直角時;則需要將轉速降低為上表之50~70%,切削量為上表之50~80%。

3. 請以吹氣方式(Air blow) 或油霧(Oil-nust) 冷卻進行切削。

4. 請依據加工形狀、切削量、機械剛性、工作夾持等使用狀況,來調整回轉速度、進給速度及切削量。

5. 當4HSR 或SHPR 進入Z 軸,而加工傾斜角度β≤2˚ 時,請將進給速度降低30~60%。

6. 上述切削條件適合於等高線加工、刀具夾持突出量4D(刃徑x4 倍以下)之場合使用,若刀具夾持突出量>4D 時,請根據個別的係數來調整回轉速度,進給速度及切削量;以防止發生顫動。

Notes:

1.Use a rigid and precise machine and holder.

2.These milling conditions are based on milling with circular interpolation at comers for milling without circular interpolation (such as right angle

comers), reduce the speed to 50~70% and the cutting depth to 50 ~80% of the conditions.

3.Recommed Oil-mist coolant or Air blow.

4.Please adjust the speed, feed and cutting depth according to actual cutting conditions.

5.When 4HSR or SHPR enters in Z axis, reduce the feed rate to 3 0~60% of the above conditions with machining incline angle (β)≤2˚.

6.These milling conditions are for a tool extension length : less than 4 x D tension, reduce the speed feed, and cutting depth in accordance with

respective coefficients, to prevent chattering.

低速高進給切削條件表

1. 請使用剛性及精準備度較佳之機械與刀桿。

2. 這些切削條件是以在轉角處可作圓形插入銑削的前提下,如果是轉角為90 度直角時;則需要將轉速降低為上表之50~70%,切削量為上表之50~80%。

3. 請以吹氣方式(Air blow) 或油霧(Oil-nust) 冷卻進行切削。

4. 請依據加工形狀、切削量、機械剛性、工作夾持等使用狀況,來調整回轉速度、進給速度及切削量。

5. 當4HSR 或SHPR 進入Z 軸,而加工傾斜角度β≤2˚ 時,請將進給速度降低30~60%。

6. 上述切削條件適合於等高線加工、刀具夾持突出量4D(刃徑x4 倍以下)之場合使用,若刀具夾持突出量>4D 時,請根據個別的係數來調整回轉速度,進給速度及切削量;以防止發生顫動。

Notes:

1.Use a rigid and precise machine and holder.

2.These milling conditions are based on milling with circular interpolation at comers for milling without circular interpolation (such as right angle

comers), reduce the speed to 50~70% and the cutting depth to 50 ~80% of the conditions.

3.Recommed Oil-mist coolant or Air blow.

4.Please adjust the speed, feed and cutting depth according to actual cutting conditions.

5.When 4HSR or SHPR enters in Z axis, reduce the feed rate to 3 0~60% of the above conditions with machining incline angle (β)≤2˚.

6.These milling conditions are for a tool extension length : less than 4 x D tension, reduce the speed feed, and cutting depth in accordance with

respective coefficients, to prevent chattering.

低速高進給切削條件表

Low-Speed High-Feed Milling Conditions

| 被削材 Work Material |

炭素鋼. 合金鋼 (~30HRC) Carbon steel, Alloy steel S50C, SCM, 鑄鐵FC250 等AISI 1049, Cast iron |

合金鋼. 工具鋼 (30~45HRC) Alloy steel, Tool steel 預硬鋼, SKD61, NAK 等Prehardned steel, AISI H13 |

熱處理鋼 (45~55HRC) Hardned steel SKD61, SKD11, NAK, STAVAX 等 AISI H13 |

熱處理鋼 (55~65HRC) Hardned steel SKD11 AISI D2 等 |

||||||||

| 切削速度 Cutting Speed |

高速條件 | 高速條件 | 高速條件 | 高速條件 | ||||||||

| 直徑 (mm) Diameter |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

回轉數 (min-1) Speed |

進給速度 mm/min Feed Rate |

||||

| 3 | 10000 | 5200 | 7000 | 3600 | 5000 | 2400 | 3000 | 900 | ||||

| 4 | 7600 | 5800 | 5200 | 3800 | 3800 | 2600 | 2200 | 1000 | ||||

| 5 | 6000 | 6000 | 4200 | 4200 | 3000 | 2700 | 1800 | 1000 | ||||

| 6 | 5000 | 6000 | 3600 | 4200 | 2600 | 2700 | 1600 | 1000 | ||||

| 8 | 3800 | 6000 | 2600 | 4200 | 2000 | 2700 | 1200 | 1000 | ||||

| 10 | 3000 | 6000 | 2200 | 4200 | 1600 | 2700 | 900 | 1000 | ||||

| 12 | 2600 | 6000 | 1800 | 4200 | 1200 | 2700 | 800 | 1000 | ||||

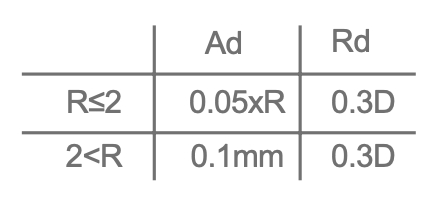

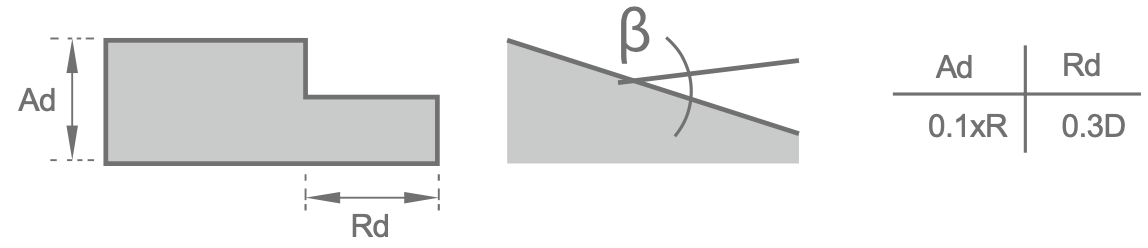

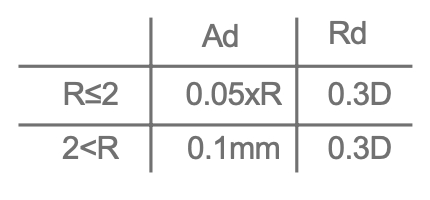

切削量基準 Depth of cut D( 直徑 Dia.) |

|

|

|

|||||||||